Blog Layout

Why HVAC Capacitors Fail: What Homeowners Need to Know

January 2, 2025

Why HVAC Capacitors Fail: What Homeowners Need to Know

If you’ve ever experienced an issue with your air conditioner or heat pump, there’s a good chance the culprit was a failed capacitor. Capacitors are small but essential components of your HVAC system. They provide the initial boost of energy needed to start the motors and keep them running efficiently. When a capacitor fails, it can bring your entire system to a halt. Here’s what you need to know about why capacitors fail and how to prevent it.

What is an HVAC Capacitor?

Capacitors store and release energy to power the motors in your HVAC system, including the compressor, blower, and fan. There are two main types of capacitors used in HVAC systems:

Start Capacitors: Provide the extra energy needed to start the motor.

Run Capacitors: Maintain a consistent flow of energy to keep the motor running.

Common Reasons Capacitors Fail

While capacitors are designed to last for several years, various factors can cause them to fail prematurely. Here are some of the most common reasons:

Overheating

High outdoor temperatures and poor ventilation around your HVAC unit can cause capacitors to overheat. Excessive heat breaks down the internal components, leading to failure.

Voltage Fluctuations

Power surges or inconsistent voltage supply can damage the delicate electrical components inside the capacitor. This is particularly common during storms or in areas with unstable power grids.

Age and Wear

Over time, capacitors naturally degrade and lose their ability to hold a charge. Most capacitors have a lifespan of 5-10 years, depending on usage and environmental conditions.

Poor Quality Components

Cheaper, low-quality capacitors are more likely to fail prematurely. Investing in a high-quality capacitor can extend the life of your system.

Electrical Overload

If your HVAC system is working harder than usual—due to dirty coils, a clogged filter, or an undersized unit—the capacitor can become overloaded and fail.

Physical Damage

Debris, corrosion, or mishandling during installation or maintenance can physically damage the capacitor and lead to failure.

Signs of a Failing Capacitor

Recognizing the early signs of a failing capacitor can help you address the issue before it causes more significant damage:

System Won’t Start: If the motors don’t start or take longer than usual to start, the capacitor may be the issue.

Humming Noise: A failing capacitor can produce a low humming noise as it struggles to function.

Reduced Cooling or Heating Efficiency: When the motors don’t run properly, your system’s performance will suffer.

Frequent Cycling: The system may turn on and off more frequently than normal.

Burning Smell: Overheating capacitors can emit a burning smell, indicating an urgent need for repair.

How to Prevent Capacitor Failure

While capacitor failure can’t always be avoided, regular maintenance and care can significantly reduce the risk:

Schedule Annual HVAC Maintenance

A professional technician can inspect and test your capacitor during routine maintenance, identifying potential issues early.

Ensure Proper Ventilation

Keep the area around your outdoor unit clear of debris and vegetation to prevent overheating.

Use a Surge Protector

Installing a surge protector can shield your HVAC system from power surges and voltage fluctuations.

Replace Air Filters Regularly

While replacing air filters helps maintain airflow and system efficiency, it does not directly impact the capacitor. Regular filter changes ensure the overall system doesn’t overwork, indirectly protecting all components, including the capacitor.

Invest in Quality Components

If a capacitor needs replacement, opt for a high-quality part to ensure better performance and longevity.

Final Thoughts

Capacitors are small but mighty components that play a critical role in the operation of your HVAC system. Understanding why they fail and taking proactive steps to prevent issues can save you from unexpected breakdowns and costly repairs. If you suspect a capacitor problem, it’s best to call a professional technician to diagnose and fix the issue promptly.

By 7001715912

•

February 13, 2025

Should I Replace My A/C System or Have It Repaired? A Comprehensive Guide for Homeowners Weighing the Options When your air conditioning system starts acting up, you’re faced with a big decision: should you repair it or replace it? As a homeowner, understanding when to fix your existing unit versus when to invest in a new one can save you time, money, and frustration. Let’s break down the key factors to consider when making this decision. Age of Your A/C System A well-maintained central A/C unit typically lasts 10-15 years. If your system is approaching or exceeding this range, replacement might be the best long-term option. Newer models are more energy-efficient and come with updated technology that can help lower utility bills. Frequency and Cost of Repairs If your system requires frequent repairs or if a single repair costs more than 50% of a new system, replacement is often the more economical choice. Minor repairs like capacitor replacements or refrigerant recharges may be worth fixing, but major components like compressors or evaporator coils can be costly. Energy Efficiency and Utility Bills Older systems are less efficient and can drive up your energy bills. If your SEER (Seasonal Energy Efficiency Ratio) rating is below 14, upgrading to a new unit could significantly reduce your monthly cooling costs. The higher the SEER rating, the more efficient the system. Refrigerant Type If your system uses R-22 refrigerant (which has been phased out), repairs could be more expensive due to limited supply. Newer systems now use A2L refrigerants, which are more environmentally friendly and energy-efficient compared to older R-410A units. Comfort and Performance Are you noticing uneven cooling, high humidity, or excessive noise? These issues could indicate your system is struggling. A replacement may offer better comfort, quieter operation, and improved air quality. Incentives and Rebates Many local utility companies and manufacturers offer rebates for upgrading to energy-efficient systems. Plus, new federal tax credits may be available for certain high-efficiency A/C units. Final Decision: Repair or Replace? Repair if: The system is under 10 years old, repairs are minor and infrequent, and energy bills are reasonable. Replace if: The unit is over 10-15 years old, repairs are costly, energy bills are high, or you experience frequent breakdowns. Need Expert Advice? At Capital City Comfort, we help homeowners make informed decisions about their HVAC systems. Whether you need a repair or a full system replacement, our expert technicians are here to provide honest recommendations and top-notch service. Contact us today for a consultation!

By 7001715912

•

February 11, 2025

If you’ve been shopping for a new air conditioning system or have had an HVAC technician mention changes in refrigerants, you might be wondering: What’s going on with these new refrigerants? Why are they changing, and how does it affect homeowners like you? Let’s break it down. Why Are Refrigerants Changing? The HVAC industry is shifting toward more environmentally friendly refrigerants due to government regulations aimed at reducing greenhouse gas emissions. Older refrigerants, like R-22 (Freon), have already been phased out due to their harmful effects on the ozone layer. Now, R-410A, the current industry standard, is being replaced by new refrigerants with lower global warming potential (GWP) to meet federal and international climate goals. What Are the New Refrigerants? The leading replacement options for R-410A include: R-32 – A single-component refrigerant with a lower GWP than R-410A, already in use in many parts of the world. R-454B (Puron Advance) – A blend designed to replace R-410A with a significantly lower GWP while maintaining similar efficiency. These new refrigerants are being adopted to comply with regulations such as the AIM Act, which aims to phase down the use of hydrofluorocarbons (HFCs) in HVAC systems. What Does This Mean for Homeowners? 1. Your Older System Is Still Functional (For Now) If your current AC unit uses R-410A, you don’t need to panic. R-410A will still be available for servicing existing systems, but costs may rise as production decreases. 2. New HVAC Systems Will Use New Refrigerants When it’s time to replace your air conditioner or heat pump, your new system will likely use one of these environmentally friendly refrigerants. 3. No Drastic Cost Savings Expected While these new refrigerants are better for the environment, they do not necessarily translate into significant cost savings for homeowners. Efficiency improvements are more dependent on the overall design and quality of the HVAC system rather than the refrigerant alone. However, newer systems that use these refrigerants are designed to meet updated efficiency standards, which could provide some energy savings. 4. Service & Repairs Might Change New refrigerants often require updated equipment and training for HVAC technicians. If you’re planning a system upgrade, ensure your HVAC provider is certified to handle these newer refrigerants. 5. Flammability & Leak Detection Requirements The new refrigerants, R-32 and R-454B, are classified as mildly flammable (A2L rating). While they are safe when handled properly, additional precautions are necessary. New HVAC systems using these refrigerants are designed with built-in leak detection systems to ensure safety and compliance with updated regulations. These systems typically lock the indoor fan ON to displace the leaking refrigerant, alerting homeowners to potential issues and adding an extra layer of protection. Should You Upgrade Now or Wait? If your current system is working well, there’s no immediate need to replace it. However, if your HVAC system is over 10-15 years old and you’re considering an upgrade, investing in a system that uses the new refrigerants could be a smart long-term decision. Final Thoughts Refrigerants are evolving to become more eco-friendly, and while this change may seem overwhelming, it ultimately benefits both homeowners and the environment. If you have questions about how these refrigerant changes impact your home, Capital City Comfort is here to help. Our expert technicians can guide you in choosing the best system for your needs, ensuring you stay comfortable while keeping up with industry advancements. Ready to learn more or schedule a consultation? Contact Capital City Comfort today!

By 7001715912

•

January 30, 2025

Don't Fall for a Cheap Ductless System: Just Buy Mitsubishi or Daikin When it comes to investing in a ductless HVAC system for your home, it can be tempting to opt for a cheap, off-brand model to save a few bucks. After all, ductless systems are already a bit pricier than traditional ones. But here's the thing: skimping on quality with a low-cost system can lead to bigger issues down the line. To get the most out of your ductless HVAC system, it’s worth investing in a trusted, high-quality brand like Mitsubishi or Daikin. Here's why. Why Cheap Ductless Systems Aren't Worth It Lower Efficiency & Higher Operating Costs One of the main selling points of ductless systems is their energy efficiency. They’re designed to heat and cool your home without the need for ducts, saving you money on energy bills. However, cheaper brands often cut corners in their design and components, leading to systems that aren't as efficient as their pricier counterparts. As a result, you might find yourself spending more on energy bills over time, negating any initial savings. Shorter Lifespan & Increased Repair Costs The build quality of budget ductless systems is often inferior to top-tier brands like Mitsubishi and Daikin. This means they can break down sooner, and the need for repairs can become a frequent headache. The cost of ongoing repairs can quickly add up, making that “cheap” system not such a great deal after all. On the other hand, well-established brands are known for their longevity and reliability, giving you peace of mind and fewer maintenance expenses in the long run. Limited Features & Inconsistent Comfort Cheap ductless systems might lack the advanced features that come with premium models. For instance, brands like Mitsubishi and Daikin offer state-of-the-art technology that allows you to control temperature and airflow more precisely. This means more consistent and comfortable temperatures throughout your home. Cheaper systems, however, might not offer the same level of comfort and precision, leaving you with hot or cold spots in your home and less control over your environment. Subpar Warranty & Support One area where cheaper ductless systems often fall short is in their warranty and customer support. Brands like Mitsubishi and Daikin typically provide excellent warranties and have established customer service teams to help with any issues. Budget brands, on the other hand, may offer limited warranties, poor customer service, or even no support at all when things go wrong. This can leave you stranded when something needs fixing, leading to costly repairs or replacement sooner than you'd like. The Mitsubishi and Daikin Difference When it comes to ductless HVAC systems, Mitsubishi and Daikin are two brands that consistently lead the pack. Here’s what makes them stand out: Energy Efficiency : Both brands are pioneers in energy-efficient technology, helping homeowners save on their monthly utility bills. Reliability : Mitsubishi and Daikin have built their reputations on providing reliable, durable systems that last for many years, with fewer repairs and maintenance costs. Innovative Features : These companies offer cutting-edge features like advanced filtration systems, smart thermostats, and whisper-quiet operation that make your home more comfortable and easier to manage. Comprehensive Warranty : Mitsubishi and Daikin offer excellent warranties and customer support, so if something goes wrong, you’re covered. This added assurance can give you peace of mind for years to come. One of the critical factors to consider when purchasing a ductless HVAC system is the availability of parts and local support. If you choose a cheap, off-brand system that doesn't have a local distributor, you're opening yourself up to several potential headaches that can make maintenance and repairs difficult. Here's how the absence of a local distributor can limit your access to essential parts and support: 1. Longer Wait Times for Parts Without a local distributor, parts for your HVAC system may need to be ordered from a distant location or even overseas. This means that, in the event of a malfunction or repair, you could be waiting weeks—or even longer—for the necessary components to arrive. During that time, you could be left without heat or cooling, making your home uncomfortable. On the other hand, well-established brands like Mitsubishi and Daikin usually have a strong network of local distributors, which means parts are readily available when you need them. This cuts down on wait times and ensures a faster turnaround for repairs. 2. Difficulty Finding Qualified Technicians Even if you manage to find the parts you need, you may run into another problem: finding a qualified technician who is familiar with your system. HVAC contractors typically work with specific brands and may not be trained to repair or service lesser-known, off-brand systems. If there’s no local distributor, you could have a hard time finding a technician with the necessary expertise. Brands like Mitsubishi and Daikin, however, have widespread recognition and a broad network of trained professionals. These technicians are familiar with the ins and outs of the systems, ensuring that repairs are done quickly and correctly. 3. Limited Warranty Support Warranty claims are another area where having a local distributor can make a huge difference. If your system breaks down and you need to file a warranty claim, the process can be much more complicated without a local distributor. You may face delays in processing your claim, and since parts are harder to get, the warranty may not cover repair costs in a timely manner. With reputable brands like Mitsubishi and Daikin, local distributors are part of a well-established network, ensuring that any warranty claims are handled efficiently and that you receive the support you need without unnecessary delays. 4. Inconsistent Customer Support If you need technical support for troubleshooting or advice, relying on an off-brand system without a local distributor can lead to poor customer service experiences. Responses may be slow, or the support team might not be as knowledgeable about the specific issues with your model. With a local distributor for established brands like Mitsubishi or Daikin, customer service is generally more responsive, and you’ll have access to technical support from people who are well-trained in their products. This gives you the confidence that your questions will be answered, and your system will get the care it needs. 5. Higher Costs for Emergency Repairs When something goes wrong with your HVAC system and you don’t have easy access to local parts or support, emergency repairs can become much more expensive. Without a local distributor, technicians may need to source parts from further away, which adds to the overall cost of the repair. If a critical part is unavailable, you may be stuck with temporary fixes or higher service charges while waiting for parts to arrive. With Mitsubishi and Daikin, however, the presence of local distributors ensures that both parts and support are readily available, often leading to more affordable and efficient emergency repairs. Conclusion Choosing a ductless HVAC system from a brand without a local distributor can severely limit your ability to maintain and repair your system when issues arise. Long wait times for parts, difficulties finding trained technicians, and poor warranty and customer support can leave you frustrated and stuck. On the other hand, well-known brands like Mitsubishi and Daikin offer the reassurance of a reliable network of distributors, parts, and skilled professionals, making it much easier to keep your system running smoothly. When it comes to long-term comfort and peace of mind, it’s worth investing in a brand that offers local support.

By 7001715912

•

January 26, 2025

How Private Equity Is Killing Our Industry In recent years, private equity firms have entered the HVAC industry with the promise of innovation, growth, and profitability. On the surface, this sounds like a win for everyone: companies grow, customers get better service, and the industry becomes more competitive. However, the reality is far less optimistic. Behind the scenes, private equity's involvement has fundamentally changed the way HVAC businesses operate—and not always for the better. Here’s a closer look at how private equity is impacting our industry and why it might not be the golden ticket it’s often portrayed to be. 1. Profit Over People Private equity firms operate with one goal in mind: maximizing profits. While there’s nothing wrong with making money, this often comes at the expense of employees, customers, and long-term business health. Here’s how it plays out: Cost-Cutting Measures: To boost short-term profitability, many private equity-owned HVAC companies slash budgets for training, quality tools, and even wages. Pressure on Technicians: Employees are often pushed to upsell services and products aggressively, even when they may not be in the customer’s best interest. Reduced Customer Focus: Companies focus more on hitting quarterly financial targets than providing exceptional customer service. 2. The Rise of Monopolies Private equity firms often buy multiple smaller HVAC businesses within a region, consolidating them under one brand. While this can create economies of scale, it also reduces competition and limits customer choice. Higher Prices: With fewer competitors in the market, private equity-backed companies can increase service prices without fear of losing customers. Homogenized Service: Instead of tailoring services to local needs, these larger companies often implement one-size-fits-all solutions that lack the personal touch smaller businesses offer. 3. Erosion of Small Businesses Private equity’s aggressive acquisition strategy has led to the decline of locally-owned HVAC businesses, which have long been the backbone of the industry. Here’s why this matters: Community Connection: Small, family-owned businesses are often deeply rooted in their communities, offering personalized service and genuine care. Fair Competition: Private equity-backed firms have more resources to outspend small businesses on advertising, making it harder for independents to compete. Loss of Identity: As local businesses are absorbed into larger conglomerates, the industry loses its diversity and charm. 4. Short-Term Thinking Private equity investments are typically designed to generate significant returns within 5-7 years. This focus on short-term profits can be detrimental to the long-term health of HVAC companies. Deferred Maintenance: Critical investments in technology, employee development, and infrastructure are often delayed to save costs. Overworked Employees: To meet aggressive financial targets, technicians and staff are often overburdened, leading to burnout and high turnover rates. Damaged Reputations: Customers notice when service quality declines, which can tarnish a company’s reputation even after private equity exits. 5. What This Means for Customers Private equity’s involvement doesn’t just affect companies; it has a direct impact on customers as well: Decreased Trust: Customers may feel pressured by aggressive upselling tactics, leading to a breakdown in trust. Inconsistent Service Quality: As companies prioritize profits, the quality of installations and repairs can suffer. Higher Costs: Consolidation and reduced competition often mean customers pay more for services without seeing an improvement in quality. 6. What Can Be Done? While the influence of private equity in HVAC isn’t going away anytime soon, there are ways to mitigate its impact: Support Local Businesses: Choose locally-owned HVAC companies that prioritize customer satisfaction and community engagement. Do Your Research: Before hiring an HVAC company, look into their ownership and reputation. Online reviews and word-of-mouth recommendations can help you find businesses that align with your values. Demand Transparency: Ask questions about pricing, services, and warranties to ensure you’re getting a fair deal. Conclusion Whenever you need service to your heating and air system, Do your research. Find a locally owned company. Call us at Capital City Comfort. We promise to never sell you something you don't need, and we don't pay our technicians based on sales!

By 7001715912

•

January 21, 2025

What is a Heat Pump and How Does It Work? As homeowners increasingly seek energy-efficient and environmentally friendly heating and cooling solutions, heat pumps have emerged as a popular option. But what exactly is a heat pump, and how does it work? Let’s dive into the details to help you understand this innovative technology. What is a Heat Pump? A heat pump is a versatile home heating and cooling system that transfers heat from one place to another, rather than generating heat directly. It can be used to heat your home in the winter and cool it in the summer, offering a two-in-one solution for year-round comfort. How Does a Heat Pump Work? At its core, a heat pump operates based on the principles of heat transfer. Here’s a breakdown of how it functions in both heating and cooling modes: Heating Mode: Heat Absorption: The heat pump extracts heat from the outdoor air, ground, or water (depending on the type of heat pump) even in cold temperatures. Compression: The absorbed heat is then compressed, increasing its temperature. Heat Distribution: The heated air is distributed throughout your home via ductwork or through a ductless system. Cooling Mode: Heat Extraction: In cooling mode, the heat pump works in reverse. It absorbs heat from inside your home. Heat Release: The absorbed heat is released outdoors, cooling the air inside your home. Air Circulation: Cool air is then circulated through the home, reducing indoor temperatures. Types of Heat Pumps Air-Source Heat Pumps: These are the most common and extract heat from the air outside your home. Ground-Source (Geothermal) Heat Pumps: These use the stable temperature of the ground to provide heating and cooling. Water-Source Heat Pumps: These draw heat from a water source, such as a pond or a well. Benefits of a Heat Pump Energy Efficiency: Heat pumps are highly efficient because they move heat rather than generate it, reducing energy consumption. Lower Operating Costs: Due to their efficiency, heat pumps can lower your utility bills compared to traditional heating and cooling systems. Environmentally Friendly: By using renewable heat sources and reducing reliance on fossil fuels, heat pumps contribute to a lower carbon footprint. Versatility: With the ability to both heat and cool your home, heat pumps offer a comprehensive solution for your climate control needs. Considerations Before Installing a Heat Pump Climate Suitability: Heat pumps are most efficient in moderate climates. In extremely cold regions, their performance may decrease, though advancements in technology are improving cold-weather efficiency. Initial Cost: While heat pumps can offer long-term savings, the initial installation cost can be higher than traditional systems. However, incentives and rebates may be available to offset the cost. Maintenance: Regular maintenance is essential to ensure optimal performance and longevity. Conclusion Heat pumps offer a smart and sustainable way to manage your home’s heating and cooling needs. By understanding how they work and the benefits they provide, you can make an informed decision about whether a heat pump is the right choice for your home. With proper installation and maintenance, a heat pump can provide comfort, efficiency, and savings for years to come.

By 7001715912

•

January 15, 2025

Most Common Problems with a Bad HVAC Installation When it comes to HVAC systems, proper installation is crucial for ensuring optimal performance, efficiency, and longevity. A poorly installed HVAC system can lead to numerous issues that affect not only the system's functionality but also your comfort and energy bills. In this blog post, we'll explore some of the most common problems associated with bad HVAC installations and how they can be avoided. 1. Incorrect Sizing One of the most frequent mistakes in HVAC installation is incorrect sizing of the system. An HVAC unit that is too large or too small for your space can lead to a host of issues: Oversized Systems: These can cycle on and off frequently, leading to inconsistent temperatures, increased wear and tear, higher energy bills, and humidity issues due to inadequate dehumidification during short cycles. Undersized Systems: These may struggle to maintain the desired temperature, resulting in constant running, inadequate cooling or heating, and increased energy consumption. Proper load calculations should be performed by a qualified HVAC professional to ensure the system is appropriately sized for your home. 2. Poor Ductwork Installation Faulty ductwork can severely impact the efficiency and performance of your HVAC system. Common ductwork issues include: Leaks and Gaps: Poorly sealed ducts can leak air, reducing system efficiency and increasing energy costs. Improper Design: Ducts that are too long, have too many bends, or are improperly sized can restrict airflow, leading to uneven heating or cooling. 3. Improper Refrigerant Charge A correct refrigerant charge is essential for the efficient operation of an HVAC system. Too much or too little refrigerant can cause: Reduced Efficiency: Incorrect refrigerant levels can make the system work harder, increasing energy consumption. System Damage: Overcharging or undercharging can cause components to wear out prematurely or lead to system failure. 4. Inadequate Airflow Poor airflow can result from several factors, including improperly sized ductwork, blocked vents, or a poorly located air handler. This can cause: Uneven Temperatures: Some rooms may be too hot or too cold. Increased Wear and Tear: The system may have to work harder to compensate for the poor airflow, leading to premature breakdowns. 5. Electrical Issues Electrical problems in an HVAC system can stem from improper wiring or connections during installation. These issues can lead to: Frequent Breakdowns: Loose or incorrect wiring can cause intermittent system failures. Safety Hazards: Faulty wiring can pose a fire risk or cause electric shocks. 6. Lack of Proper Drainage An HVAC system needs a properly installed drainage system to handle the condensation produced during operation. Poor drainage can result in: Water Damage: Leaks can cause damage to ceilings, walls, and floors. Mold Growth: Standing water can lead to mold and mildew, which can affect indoor air quality and health. 7. Not Brazing with Nitrogen Brazing without nitrogen can introduce oxygen into the system, leading to oxidation inside the copper tubing. This oxidation can cause: TXV Failures: Oxidation can clog the thermostatic expansion valve (TXV), leading to system inefficiency or failure. Reduced System Longevity: The presence of oxidation and contaminants can shorten the lifespan of the HVAC system. Always use nitrogen during the brazing process to purge oxygen and prevent oxidation inside the system. 8. Improper Airflow Adjustment for Static Pressure Incorrectly adjusted airflow can result in high static pressure, which can strain the system and reduce efficiency. This can cause: Reduced Efficiency: High static pressure forces the system to work harder, increasing energy consumption. System Damage: Prolonged operation under high static pressure can lead to premature wear and tear on system components. A thorough system check is essential after installation to ensure everything is functioning correctly. Skipping this step can result in: Undetected Issues: Small problems can go unnoticed, leading to bigger issues over time. Reduced Efficiency: The system may not operate at peak efficiency, increasing energy costs and reducing comfort. Final Thoughts A bad HVAC installation can lead to a range of problems that compromise the system's performance, efficiency, and lifespan. By ensuring that your HVAC system is installed by a qualified professional who follows industry best practices, you can avoid these common issues and enjoy reliable, efficient comfort in your home. Regular maintenance and inspections can further help in identifying and addressing any potential problems early on, ensuring your system continues to operate smoothly for years to come.

By 7001715912

•

January 13, 2025

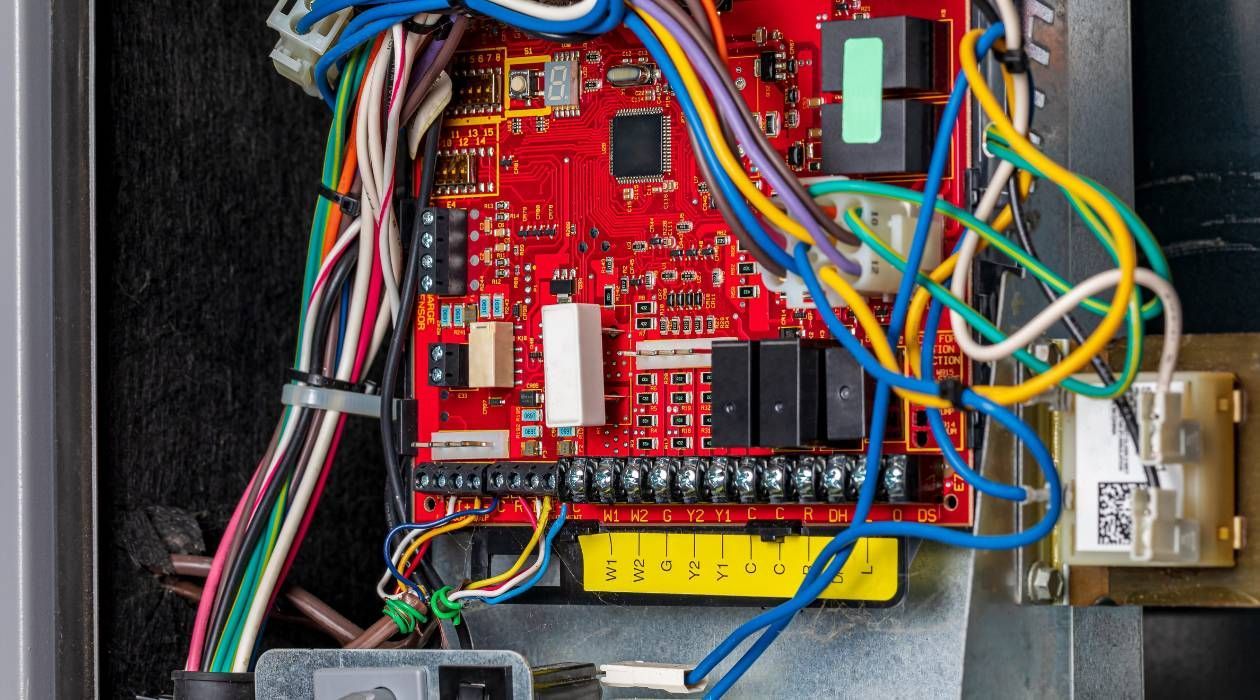

The Need for Surge Protectors for HVAC Systems with Control Boards In today's technologically advanced world, HVAC systems are more sophisticated than ever, featuring intricate control boards that manage various functions for optimal performance. However, with increased complexity comes a heightened vulnerability to electrical surges. Protecting these critical components is essential for the longevity and reliability of your HVAC system. One of the most effective ways to safeguard your investment is by installing surge protectors specifically designed for HVAC systems with control boards. Here's why surge protection is essential and how it can benefit your HVAC system. Understanding Electrical Surges An electrical surge, or transient voltage, is a sudden and brief spike in electrical power. These surges can occur due to several reasons, including: Lightning Strikes: Even distant lightning strikes can cause power surges that travel through electrical lines and damage appliances. Power Outages: When power is restored after an outage, the sudden influx of electricity can create a surge. Electrical Grid Switching: Changes in the electrical grid or switching between power sources can result in voltage spikes. Internal Surges: Everyday activities, such as turning on high-powered appliances, can cause minor surges within a home's electrical system. Why HVAC Systems Are Vulnerable Modern HVAC systems rely heavily on control boards to regulate operations such as temperature control, fan speed, and compressor function. These boards are sensitive to voltage fluctuations, making them susceptible to damage from power surges. When a surge occurs, it can: Damage Control Boards: The intricate circuitry in control boards can be easily fried by high voltage, leading to costly repairs or replacements. Disrupt System Operation: A damaged control board can cause the HVAC system to malfunction or stop working entirely. Reduce System Lifespan: Repeated exposure to surges can degrade components over time, shortening the overall lifespan of the HVAC system. Benefits of Surge Protectors for HVAC Systems Installing a surge protector for your HVAC system offers several key benefits: 1. Protection of Critical Components Surge protectors shield the control board and other sensitive components from voltage spikes, preventing damage and ensuring consistent operation. 2. Cost Savings Preventing damage to the control board and other parts can save you from expensive repairs and replacements, as well as potential downtime. 3. Increased System Longevity By protecting your HVAC system from electrical surges, you can extend its lifespan and get more value from your investment. 4. Peace of Mind Knowing that your HVAC system is protected against unpredictable power surges provides peace of mind, especially during stormy seasons. Choosing the Right Surge Protector When selecting a surge protector for your HVAC system, consider the following factors: Compatibility: Ensure the surge protector is compatible with your HVAC system's voltage and specifications. Response Time: Look for a surge protector with a fast response time to quickly react to voltage spikes. Energy Rating: Choose a surge protector with an adequate energy rating to handle the potential surge levels in your area. Professional Installation: Have a qualified HVAC technician install the surge protector to ensure proper setup and functionality. Conclusion Surge protectors are a crucial investment for protecting HVAC systems with control boards from the damaging effects of electrical surges. By installing a surge protector, you can safeguard your system's vital components, reduce repair costs, and extend the life of your HVAC system. Consult with an HVAC professional to select and install the right surge protection solution for your system, ensuring reliable performance and peace of mind.

By 7001715912

•

January 8, 2025

Non-Invasive Testing for Refrigerant Charge: A Game Changer in HVAC Maintenance Maintaining the correct refrigerant charge in an HVAC system is crucial for its efficiency and longevity. Traditionally, checking the refrigerant charge involves invasive methods that require accessing the system, which can lead to potential refrigerant leaks or system contamination. However, non-invasive testing methods are revolutionizing HVAC maintenance by offering accurate diagnostics without the risks associated with traditional techniques. Let's explore how non-invasive testing works and its benefits. What Is Non-Invasive Testing for Refrigerant Charge? Non-invasive testing methods allow technicians to assess the refrigerant charge in an HVAC system without opening the system or connecting gauges that might disturb the sealed environment. These techniques rely on external measurements and sophisticated diagnostic tools to determine whether the refrigerant level is within the optimal range. Common Non-Invasive Methods: Temperature Measurements: Surface Temperature Sensors: Technicians use infrared thermometers or surface temperature sensors to measure the temperature at various points on the HVAC system's components, such as the evaporator and condenser coils. Delta T Calculations: The temperature difference (ΔT) between the return and supply air is analyzed to infer the system's cooling performance and refrigerant charge status. Pressure Readings: Non-Invasive Pressure Sensors: These sensors can estimate the system's internal pressures by measuring vibrations or sound waves without directly accessing the refrigerant lines. System Performance Metrics: Power Consumption Analysis: By monitoring the electrical consumption of the system, technicians can determine if the system is operating efficiently or if a refrigerant charge issue might be affecting performance. Airflow Measurement: Ensuring proper airflow across the coils can also indicate whether the system is under or overcharged. Benefits of Non-Invasive Testing 1. Enhanced Safety and Environmental Protection: Reduced Risk of Leaks: Since the system remains sealed, there is no risk of accidentally releasing refrigerant into the atmosphere, which is crucial for both safety and environmental protection. Less System Contamination: Non-invasive methods prevent contaminants from entering the system, which can occur when gauges or hoses are connected. 2. Time Efficiency: Faster Diagnostics: Non-invasive techniques can quickly provide insights into the system's performance, saving time during routine maintenance or troubleshooting. Minimized Downtime: HVAC systems can continue operating during non-invasive tests, minimizing disruption to occupants. 3. Cost Savings: Lower Maintenance Costs: By reducing the need for refrigerant recovery and recharging, non-invasive testing lowers maintenance costs. Extended Equipment Life: Accurate diagnostics help in identifying issues early, preventing extensive damage and prolonging the life of the HVAC system. 4. Improved Customer Satisfaction: Transparent Reporting: Technicians can show real-time data and explain findings to customers without invasive procedures, building trust and satisfaction. When to Use Non-Invasive Testing Non-invasive testing is ideal for routine maintenance, initial diagnostics, and when quick checks are needed to confirm system performance. However, if non-invasive methods indicate a potential issue, further invasive testing might be necessary to confirm the diagnosis and perform repairs. Conclusion Non-invasive testing for refrigerant charge is transforming HVAC maintenance by offering a safer, faster, and more cost-effective way to ensure systems operate efficiently. By embracing these advanced diagnostic methods, HVAC professionals can enhance service quality while protecting both the environment and the integrity of the systems they maintain. If you're looking to optimize your HVAC maintenance practices, consider integrating non-invasive testing into your service routine.

By 7001715912

•

January 6, 2025

What Is a Soft Start Kit, and Do I Need One? If you’ve ever noticed your air conditioning system or other large appliances making a loud jolt when they start up, you’ve witnessed the strain these systems experience during startup. This is where a soft start kit comes in. But what exactly is a soft start kit, and is it something you should consider for your equipment? Let’s break it down. What Is a Soft Start Kit? A soft start kit is a device that reduces the inrush of electrical current that occurs when a motor starts. Motors, such as those in HVAC systems, typically require a large amount of energy to get going. This sudden surge of power can: Create a loud, jarring noise Cause wear and tear on the motor and other components Trigger electrical issues, such as tripped breakers or power fluctuations A soft start kit smooths out the startup process by gradually increasing the power to the motor. This controlled startup reduces the strain on your system and minimizes the noise associated with standard motor startups. Benefits of a Soft Start Kit Installing a soft start kit can provide several benefits, including: Reduced Wear and Tear: By easing the initial electrical load, a soft start kit can extend the lifespan of your motor and associated components. Lower Noise Levels: The gradual startup reduces the loud clunk or jolt that can occur when a motor kicks on. Improved Electrical Performance: Minimizing the power surge during startup reduces the risk of electrical disturbances, such as flickering lights or power dips, instead of focusing on breaker trips. Energy Efficiency: While the main purpose is to smooth the startup process, some users may see slight energy savings over time due to less frequent motor strain. Better Compatibility with Backup Generators: Soft start kits can make HVAC systems and other motors more compatible with backup power sources, ensuring smoother operation during outages. Do You Need a Soft Start Kit? Whether you need a soft start kit depends on your specific situation. Here are some scenarios where installing one might be beneficial: Frequent Motor Startups: If your air conditioner, heat pump, or other motor-driven equipment cycles on and off frequently, a soft start kit can help reduce wear and tear. Older Systems: Older HVAC systems often experience more strain during startup, making a soft start kit a valuable addition. Noise Concerns: If the noise from your system’s startup is disruptive, a soft start kit can significantly reduce it. How to Get a Soft Start Kit Installed If you think a soft start kit is right for you, give us a call. we can assess your system’s needs and ensure proper installation. It’s important to choose a kit compatible with your equipment and have it installed by a professional to avoid potential damage or safety issues. Final thoughts A soft start kit can be a valuable investment for improving the performance, reliability, and longevity of your HVAC system or other motor-driven equipment. If you’re dealing with noise, frequent maintenance, or electrical issues, this simple upgrade could make a big difference. Call us to determine if a soft start kit is the right solution for you.

SERVING

,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

and Surrounding Areas

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Hours:

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

CONTACT US

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Hi. Do you need any help?

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2025

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.

Share On: